Quality Assurance & Testing

Best innovations in quality assurance

At Morse-o-Tool, we believe that precision tooling excellence starts with uncompromising quality assurance and testing. Every punch, die, and component we produce undergoes rigorous inspection protocols to ensure compliance with international pharmaceutical standards and flawless performance in production environments

Our quality innovations include advanced metrology, surface finish analysis, hardness testing, and coating adherence validation — all designed to extend tool life, reduce downtime, and enhance tablet quality.

Planning & Strategy

Our quality assurance strategy integrates at every stage — from material selection to final inspection. We plan every detail to meet regulatory expectations (USFDA, EU GMP) and your unique operational needs:

- Dimensional verification using precision instruments

- Surface roughness and coating integrity tests

- Hardness and microstructure checks

- Documentation and compliance reporting

Our team combines advanced testing equipment with deep expertise to ensure every tool meets the most stringent pharmaceutical production requirements. Watch how we deliver reliable, consistent tooling solutions that support your manufacturing goals.

Inspection Reports for Complete Transparency

At Morse-o-Tool, we provide a detailed inspection report with every shipment, ensuring transparency and confidence in your tooling purchase. Each report documents all critical dimensions and quality parameters, including:

Tip size and barrel size

Working length, total length, and cup depth

Die diameter, die height, and Die Go/NoGo/D gauge checks

Concentricity of punches and dies

Hardness report

Coating report

These comprehensive inspections guarantee that every punch and die you receive meets your press compatibility, formulation, and regulatory needs while maintaining the highest standards of accuracy and performance.

In-House Production: Its Impact on Quality

Before choosing a tooling partner, always ask your vendor if they have an in-house manufacturing facility with all critical processes under one roof. This is a crucial factor that directly impacts the quality, consistency, and reliability of the tablet punches and dies you receive.

Why In-House Production Matters:

Complete Quality Control:

Each stage of production, from raw material selection to final inspection, is closely monitored, ensuring every tool meets tight tolerances and performance standards.

Consistent Precision:

Critical processes like CNC machining, VMC operations, grinding, polishing, and laser marking performed in-house reduce variability and ensure consistent tool geometry, surface finish, and coating integrity.

Faster Turnaround:

With no dependency on external vendors for key processes, timelines are controlled internally, ensuring prompt deliveries without compromising on inspection and validation.

Confidentiality and Customization:

In-house facilities protect design confidentiality while enabling rapid iterations, custom tooling solutions, and formulation-specific geometry modifications as needed.

Longer Tool Life:

Controlled processes result in superior surface finishes, accurate hardness, and precise coatings, reducing sticking, wear, and downtime in your tablet production lines.

At Morse-o-Tool, we maintain over 95% in-house manufacturing for our punches and dies, ensuring that the tooling you receive is high-quality, reliable, and consistent, helping your production achieve the highest standards in tablet quality and operational efficiency.

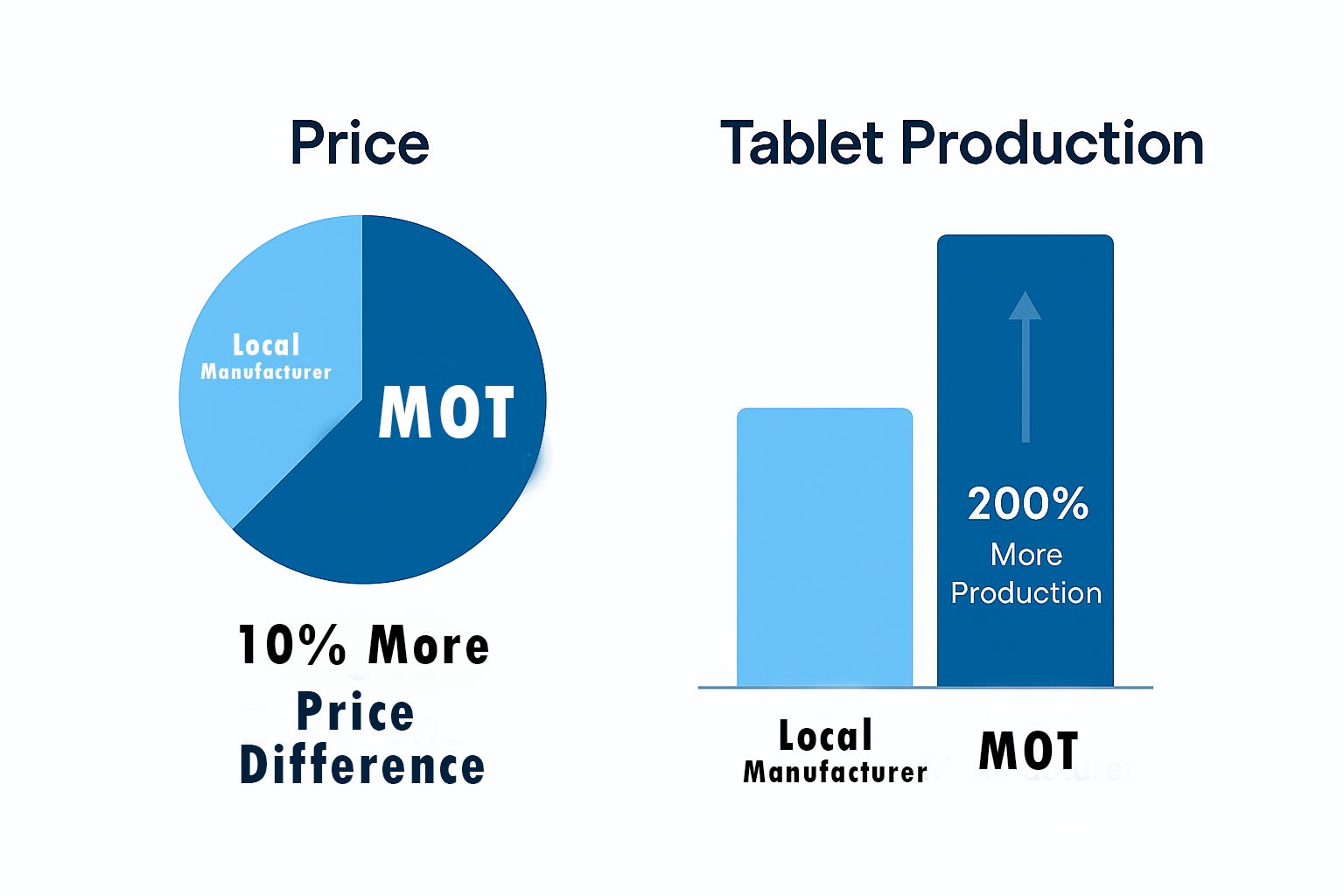

Why Quality Tooling Matters: True Cost vs. Production Output

It’s tempting to choose cheaper local tooling to save upfront costs. However, tooling quality has a direct impact on your tablet production efficiency, output, and overall profitability.

The Hidden Cost of Cheap Tooling

Upfront Price Difference: Local, low-quality punches and dies may cost 30–50% less than premium tooling.

Output Loss: These cheaper tools often produce significantly fewer tablets before requiring replacement due to rapid wear, sticking, or breakage.

Production Downtime: Poor-quality tools lead to frequent stoppages, cleaning, and rejections, increasing operational costs.

Real Impact on Your Bottom Line

Using best-in-class tooling from a reputed manufacturer like Morse O Tool may cost more initially, but you gain:

200% More Tablets Produced: Premium tooling can produce 2–3x more tablets over its lifecycle compared to cheaper alternatives.

Consistent Tablet Quality: Reduced sticking, uniform weight, and accurate breaklines minimize rejections.

Reduced Downtime: Fewer stoppages and cleaning cycles improve machine efficiency.

Lower Cost Per Tablet: More tablets produced per tooling investment means a lower effective production cost.

Example:

A local punch and die set may cost ₹1,000–₹1,500 but produce only tablets worth ₹10–20 lakhs.

A premium Morse O Tool set may cost ₹3,000 but can produce tablets worth ₹30 lakhs or more, providing superior ROI.

Invest in Quality, Maximize Your Profits

Tooling is not an expense; it is an investment in your manufacturing efficiency. Choosing high-quality tooling ensures you get maximum output, consistent quality, and the lowest cost per tablet, helping your business scale profitably while maintaining your reputation in the pharmaceutical market.

Questions? You’re covered

Every tool is tested for dimensional accuracy, surface finish, coating adhesion, and hardness. Full reports accompany every shipment.

Absolutely — we tailor QA protocols to match your specific tablet press, formulation challenges, and regulatory requirements.

We provide complete QA documentation — including material certificates, dimensional reports, and coating validation — at the time of tool delivery.

Review whether your vendor has in-house production capabilities to ensure quality control at every stage. Check their experience and contribution to the growing pharmaceutical sector, which reflects their ability to deliver reliable, high-quality tooling that meets industry standards.

At Morse-o-Tool, we use food-grade oil that is NSF approved and compliant with ISO 9001:2015 standards for storing tablet dies and punches. This prevents corrosion during storage while ensuring safety and compliance with pharmaceutical manufacturing environments.

We are always ready to help you and answer your questions