Manufacturing

Best innovations in pharmaceutical tooling manufacturing

At Morse-o-Tool, we take pride in delivering precision-crafted tablet punches, dies, and tooling components designed for the stringent demands of pharmaceutical production. Our manufacturing process combines advanced CNC machining, EDM technology, and strict quality control to ensure exceptional accuracy, durability, and compliance.

Each tool is engineered to minimize wear, reduce sticking, and support high-speed operations — helping clients achieve consistent tablet quality and efficient production.

Planning & Strategy

Our manufacturing services begin with a deep understanding of your production requirements. From material selection and coating specification to tool geometry, our team collaborates closely with you to design solutions that enhance performance and extend tool life

- Custom documentation to support validation and regulatory needs

- Brand consistency through precise engravings and design integrity

- Robust quality control systems ensuring compliance with USFDA, EU GMP, and other global standards

- Press compatibility assurance for seamless integration into existing equipment

At Morse-o-Tool, our manufacturing process combines precision engineering with advanced technology to deliver pharmaceutical tooling that meets the highest standards of quality, durability, and compliance. From raw material selection to final inspection, every tool is crafted to ensure exceptional performance in demanding production environments.

We Do It In-House

At Morse-o-Tool, we are among the few pharmaceutical tooling manufacturers who carry out more than 95% of our production processes in-house. From raw material selection to precision machining, grinding, polishing, and final inspection, maintaining in-house control allows us to ensure consistent quality, faster delivery, and competitive pricing for our customers while safeguarding design confidentiality and flexibility in production schedules.

Our team uses CAD, CAM, and rigorous validation protocols to move from design to production with speed and confidence.

In-House Production: Why 95%?

You might wonder, why only 95%?

Processes like hardening and plating require specialized chemical treatments, which, if performed within the main production facility, could affect other precision machinery and the working environment due to chemical vapors and residues. To protect our CNC, VMC, and grinding machines and ensure a clean, safe workspace, we carry out these critical processes in specialized external facilities equipped for environmental safety while maintaining our quality standards.

Our In-House Capabilities

At Morse-o-Tool, we have built a robust infrastructure with advanced machinery to handle complex pharmaceutical tooling requirements with precision and consistency:

CNC Machining: For high-accuracy shaping with tight tolerances.

VMC (Vertical Machining Centers): For precision milling and drilling operations.

Cylindrical Grinding: For achieving dimensional accuracy and superior surface finishes.

Centerless Grinding: For efficient, high-volume precision finishing.

Polishing: To create mirror-finished punches for smooth tablet ejection and reduced sticking.

Laser Marking: For permanent, high-precision identification and branding.

Inspection Systems: Advanced measuring instruments ensuring every tool meets stringent dimensional and quality requirements.

By maintaining these processes in-house, we control every step of production, ensuring our pharmaceutical dies and punches consistently meet the highest standards demanded by the industry.

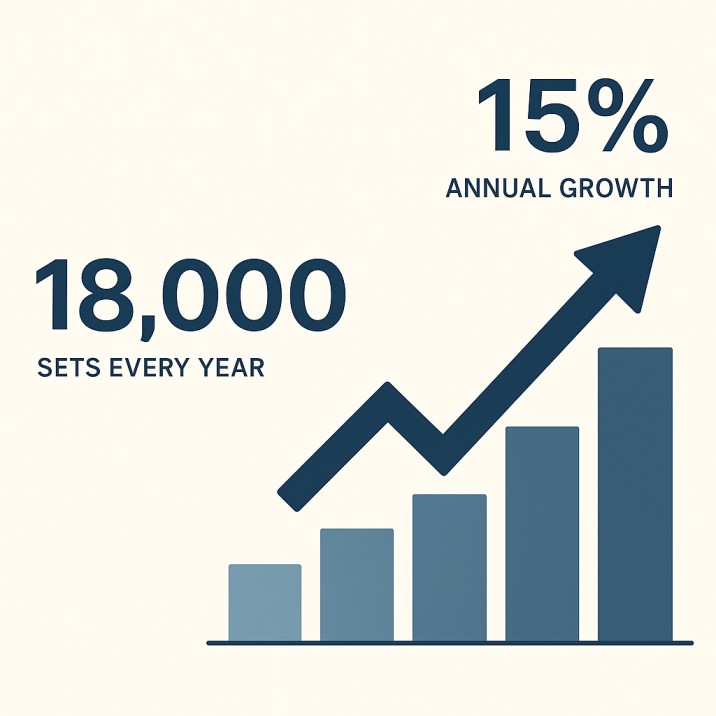

Stats

Questions? You’re covered

At Morse-o-Tool, we understand you may have questions when choosing a pharmaceutical tooling partner. From material selection and compatibility to precision standards and delivery timelines, our team is here to guide you at every step. We are committed to providing clear, transparent information so you can make confident decisions for your production needs.

We use high-grade tool steels and specialty alloys, selected based on formulation requirements, press compatibility, and durability standards. All materials comply with pharmaceutical manufacturing regulations.

Yes, we manufacture punches, dies, and components compatible with a wide range of international tablet press models. Our engineers can customize designs for specific machinery.

Our tools are manufactured under strict quality control protocols, including dimensional checks, hardness testing, and surface finish inspections, ensuring they meet USFDA, EU GMP, and other regulatory requirements.

We are always ready to help you and answer your questions