Understanding the critical factors that separate premium tooling from standard options

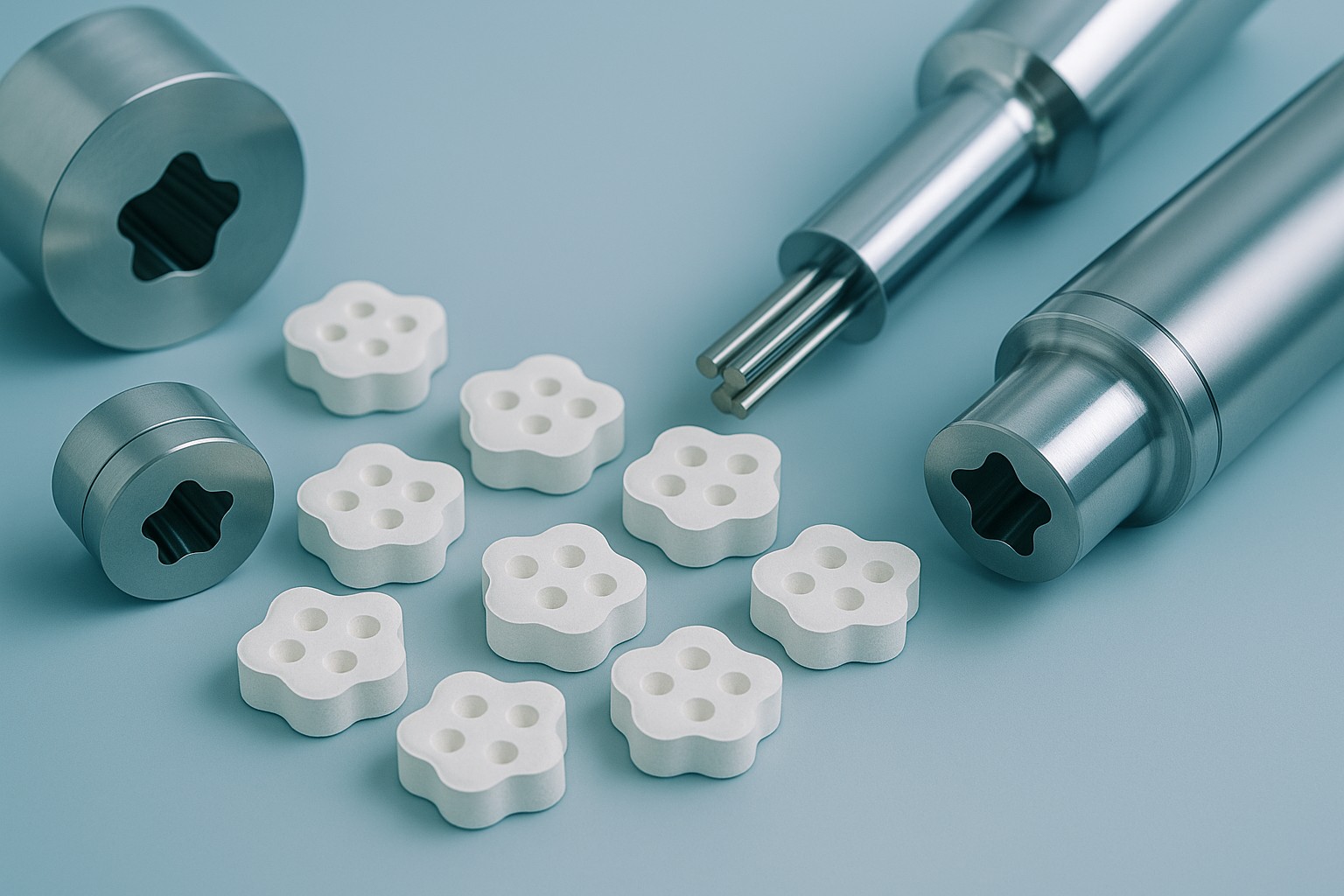

In the world of pharmaceutical manufacturing, where precision meets scale and quality is non-negotiable, one component stands as the unsung hero of tablet production: the humble tablet punch. While it may appear as a simple piece of machined metal, a high-performance tablet punch represents the convergence of advanced metallurgy, surface engineering, precision manufacturing, and intelligent design—all working in harmony to ensure every tablet meets the exacting standards required for patient safety and regulatory compliance.

The Foundation: Why Tablet Punches Matter

Every tablet you’ve ever taken began its journey under the immense pressure of a tablet punch. These precision-engineered tools, working in pairs (upper and lower punches with a die), compress pharmaceutical powders into the familiar solid dosage forms we know as tablets. The performance of these punches directly influences three critical quality attributes:

- Weight uniformity: Ensuring consistent dosing

- Tablet hardness: Affecting dissolution and stability

- Appearance: Maintaining brand integrity and patient confidence

But what transforms a basic punch into a high-performance tool capable of producing hundreds of millions of tablets while maintaining strict quality standards? The answer lies in a sophisticated understanding of materials science, surface engineering, and precision manufacturing.

The Heart of Performance: Advanced Tool Steel Selection

The foundation of any high-performance tablet punch begins with the steel from which it’s crafted. Not all tool steels are created equal, and the choice of material can mean the difference between a punch that lasts millions of cycles versus one that fails after a few hundred thousand.

The Workhorse: S7 Shock-Resisting Steel

In the pharmaceutical industry, AISI S7 has emerged as the gold standard for punch construction. This air-hardening, shock-resistant steel offers an exceptional balance of properties that make it ideal for the demanding world of tablet compression:

- Exceptional impact toughness: Withstands the repetitive pounding of high-speed rotary presses

- Optimal hardness: Achieves mid-50s HRC, providing wear resistance without brittleness

- Fracture resistance: Significantly reduces the risk of tip breakage during high-speed operation

Premium Alternatives for Specialized Applications

While S7 serves as the industry backbone, specialized formulations demand more exotic materials:

High Carbon High Chromium Steels (HCHC/D2/D3): These carbide-rich steels excel when compressing abrasive granules, such as nutraceuticals containing hard minerals. Their high carbon and chromium content creates a matrix of hard carbides that resist abrasive wear, though they sacrifice some toughness in the process.

Particle Metallurgy (PM) Steels: Representing the cutting edge of tool steel technology, PM steels like Vanadis 3V, 9V, and 10V contain fine, uniformly distributed carbides that overcome the traditional hardness-toughness trade-off. These materials are reserved for the most demanding applications where standard steels would wear out quickly.

Stainless Tool Steels: For sticky or corrosive formulations, high-chromium stainless steels like AISI 440C or M340 provide enhanced corrosion resistance and smoother product release, preventing the metal contamination that can occur with standard steels.

Surface Engineering: The Art of Coatings

Beyond the base steel, high-performance punches leverage advanced surface treatments that can multiply their service life by orders of magnitude. These coatings represent some of the most sophisticated surface engineering technologies available today.

Physical Vapor Deposition (PVD) Coatings

PVD techniques apply ultra-hard, thin ceramic layers with exceptional adhesion:

Chromium Nitride (CrN): Provides superior anti-stick properties with a homogeneous, low-porosity surface. The coating’s density and smoothness mean less product adheres to the punch, while its corrosion resistance extends tool life significantly.

Titanium Nitride (TiN): The distinctive gold-colored coating offers extremely high hardness and wear protection. TiN’s low friction properties help punches endure long production runs with minimal tip wear.

Titanium Aluminum Nitride (TiAlN): An advanced variant that combines the benefits of TiN with enhanced thermal stability, making it ideal for high-speed applications where heat generation is a concern.

Diamond-Like Carbon (DLC): The Premium Solution

For the most demanding applications, DLC coatings represent the pinnacle of surface engineering. This carbon-based coating approaches the microhardness of diamond, creating an ultra-smooth, extremely hard surface with remarkably low friction and surface energy.

The benefits are transformative:

- Outstanding wear resistance: Studies show DLC-coated punches can have 16 times the wear resistance of uncoated steel

- Exceptional anti-stick properties: Ideal for very sticky or moisture-sensitive formulations

- Thermal management: Low thermal conductivity reduces heat buildup during high-speed compression

- Chemical inertness: Prevents compounds from baking onto punch faces

Precision Manufacturing: The Tolerance Game

High-performance tablet punches are manufactured to tolerances that would be impressive in aerospace applications. In rotary tablet presses, dozens of punches must work in perfect synchronization—even tiny dimensional differences can lead to weight or hardness variations from station to station.

Critical Dimensional Control

Working Length Precision: Top-tier tooling vendors machine punches to within ±0.002 inches (±0.05 mm) in working length tolerance across a complete set. This precision ensures that each tablet receives identical compression force and fills to the same depth.

Matched Punch Sets: High-performance manufacturers often provide punch length matching reports, pairing each upper punch with a specific lower punch by length to optimize uniformity. This meticulous matching ensures consistent tablet parameters across the entire production run.

Surface Finish Standards: Critical surfaces are often polished to a mirror finish (sometimes down to 5 micro-inch Ra or better), reducing friction and eliminating micro-asperities where particles could lodge.

Design Intelligence: Engineering for Excellence

High-performance punches incorporate sophisticated design elements that address common manufacturing challenges before they occur.

Anti-Sticking Design Features

Optimized Surface Topography: Ultra-smooth surface finishes make it difficult for particles to gain a foothold, while strategic surface texturing in non-critical areas can aid in powder flow.

Advanced Cup Geometries: Carefully designed cup profiles and land areas prevent stress concentration while ensuring clean tablet release. The land (flat perimeter) area is optimized to provide strength without compromising tablet appearance.

Embossing Excellence: Logos and text are engineered with proper draft angles and depth to prevent picking while maintaining crisp definition. The embossing sits below the land edge, protecting delicate features during ejection.

Structural Optimization

Stress Distribution: Complex tablet shapes introduce uneven force distribution. High-performance punches use CAD modeling and sometimes Finite Element Analysis (FEA) to identify and reinforce stress concentration points.

Anti-Chipping Features: Microscopic corner radii and chamfers on punch edges prevent the initiation of cracks that could lead to catastrophic failure.

Advanced Manufacturing: CAD/CAM Integration

Modern high-performance punches are born in the digital realm, where Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) technologies ensure unprecedented precision and repeatability.

Digital Design Advantages

3D Modeling Precision: Engineers create detailed 3D models integrating tablet specifications, press tooling standards, and performance requirements. This allows for precise visualization and simulation before any metal is cut.

Customization Capabilities: CAD/CAM integration enables virtually unlimited customization options, from complex corporate logos to multi-tip configurations that multiply production output.

Quality Assurance Integration: Coordinate measuring machines (CMMs) and optical comparators use the CAD model as a reference, ensuring every critical dimension meets specification.

The Economics of Excellence: ROI and Long-Term Value

While high-performance punches command premium pricing, their total cost of ownership tells a compelling story of value creation.

Extended Service Life

Premium punches can demonstrate remarkable longevity—industry reports document cases where punches produced over 650 million tablets and remained in service. Even more typical scenarios show 5-10 times longer service life compared to standard tooling.

Reduced Downtime

High-performance punches reduce production interruptions by:

- Minimizing sticking-related stops for cleaning

- Extending intervals between tool changes

- Reducing unexpected failures that can damage press equipment

Quality Yield Improvements

Superior punches directly impact product quality by:

- Reducing tablet defects and waste

- Improving weight uniformity and content consistency

- Minimizing the risk of batch failures or recalls

Operational Efficiency

The indirect benefits include:

- Reduced operator intervention requirements

- Simplified maintenance procedures

- Enhanced process capability and control

Regulatory Compliance: Meeting cGMP Standards

High-performance punches support regulatory compliance through multiple pathways:

Material Documentation: Premium suppliers provide comprehensive material certifications and documentation, supporting FDA requirements for equipment contact surfaces.

Maintenance Support: Enhanced durability and designed-in maintainability support the robust SOPs required for cGMP compliance.

Traceability: Many high-performance punches include laser identification marking and come with comprehensive documentation supporting audit trail requirements.

Future Trends: Innovation Continues

The field of tablet punch technology continues to evolve, with emerging trends including:

Smart Tooling: Integration of sensors and monitoring systems to provide real-time feedback on punch condition and performance.

Advanced Coatings: Development of new coating materials and application techniques to address increasingly challenging formulations.

Additive Manufacturing: Exploration of 3D printing technologies for rapid prototyping and custom tooling production.

Sustainable Materials: Research into environmentally friendly materials and processes that maintain performance while reducing environmental impact.

Conclusion: Investment in Excellence

High-performance pharmaceutical tablet punches represent far more than premium tooling—they embody a comprehensive approach to pharmaceutical manufacturing excellence. Through the integration of advanced materials science, precision engineering, and intelligent design, these tools enable pharmaceutical manufacturers to achieve the consistency, quality, and efficiency demanded by modern healthcare.

For pharmaceutical engineers, procurement professionals, and QA/QC teams, the decision to invest in high-performance punches is ultimately an investment in manufacturing capability, product quality, and long-term operational success. In an industry where quality is not just a goal but a regulatory requirement, the difference between standard and high-performance tooling can mean the difference between meeting specifications and exceeding them—consistently, reliably, and profitably.

As the pharmaceutical industry continues to evolve toward more personalized medicines, complex formulations, and higher production volumes, the role of high-performance tablet punches becomes increasingly critical. They are, quite literally, the tools that shape the future of pharmaceutical manufacturing—one tablet at a time.

The investment in high-performance tablet punches represents a commitment to manufacturing excellence that pays dividends in product quality, operational efficiency, and regulatory compliance. In pharmaceutical manufacturing, where precision and consistency are not just goals but requirements, these sophisticated tools provide the foundation for success.