Tablet punch quality control represents a critical component of pharmaceutical manufacturing compliance, directly impacting product quality, patient safety, and regulatory approval. Understanding and implementing proper quality standards for tablet punches ensures consistent tablet production while meeting stringent FDA and ICH requirements. This comprehensive guide explores the regulatory landscape, quality control procedures, and best practices that pharmaceutical manufacturers must follow to maintain compliance and ensure product integrity.

Regulatory Framework Overview

FDA Requirements for Tablet Tooling

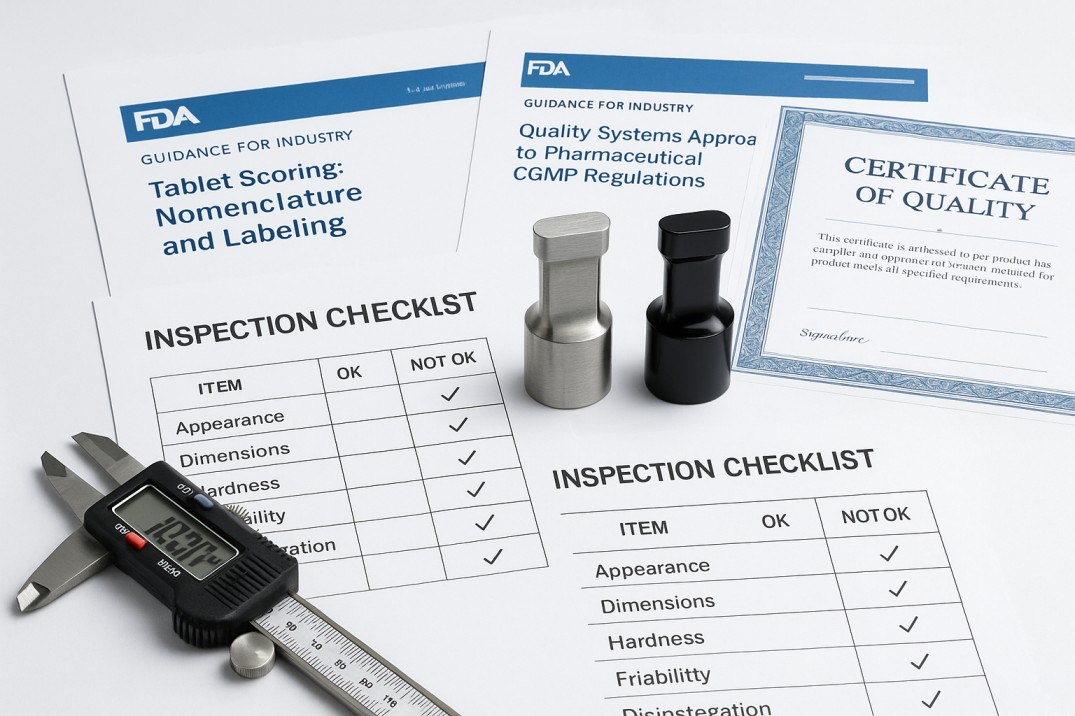

The FDA’s approach to tablet punch quality control is embedded within the broader framework of Current Good Manufacturing Practices (cGMP) outlined in 21 CFR Parts 210 and 211. While the FDA doesn’t provide specific standards exclusively for tablet punches, several key regulations directly impact tooling quality requirements:

21 CFR 211.63 – Equipment Design and Construction mandates that equipment used in manufacturing must be of appropriate design and adequate size for its intended use. This regulation requires tablet punches to be designed and manufactured to facilitate cleaning, maintenance, and operation in accordance with their intended use.

21 CFR 211.67 – Equipment Cleaning and Maintenance establishes requirements for equipment cleaning and maintenance procedures that directly impact tablet punch handling, storage, and lifecycle management. These procedures must be written and followed to prevent contamination and ensure consistent performance.

21 CFR 211.68 – Automatic, Mechanical, and Electronic Equipment addresses the validation and calibration requirements for equipment, including tablet presses and their associated tooling. This regulation impacts how tablet punches are qualified and maintained throughout their service life.

ICH Guidelines and International Standards

The International Council for Harmonisation (ICH) provides globally recognized guidelines that complement FDA requirements:

ICH Q7 – Good Manufacturing Practice for Active Pharmaceutical Ingredients establishes principles applicable to tablet punch manufacturing and quality control, particularly for API tablets where cross-contamination risks are highest.

ICH Q8 – Pharmaceutical Development emphasizes Quality by Design (QbD) principles that should be applied to tooling selection and specification. This guideline encourages manufacturers to understand how tooling variables impact final product quality.

ICH Q9 – Quality Risk Management provides frameworks for assessing risks associated with tablet punch quality and establishing appropriate control measures throughout the tooling lifecycle.

ICH Q10 – Pharmaceutical Quality System outlines the quality system elements that should govern tablet punch procurement, qualification, and ongoing management.

Material Standards and Specifications

Steel Grade Requirements

Pharmaceutical tablet punches must be manufactured from materials that meet specific quality and safety standards:

Material Composition: Tool steels used for tablet punches typically include grades such as D2, A2, or specialized pharmaceutical grades. These materials must be sourced from certified suppliers with documented material certifications including chemical composition, mechanical properties, and heat treatment records.

Hardness Specifications: Tablet punches require specific hardness ranges, typically 58-62 HRC for steel punches, to ensure adequate wear resistance while maintaining sufficient toughness. Hardness testing must be performed using calibrated equipment with documented procedures and acceptance criteria.

Surface Finish Requirements: Pharmaceutical applications demand superior surface finishes, typically 8-16 Ra (microinches), to prevent tablet sticking, facilitate cleaning, and minimize contamination risks. Surface finish measurements should be documented and verified using appropriate instrumentation.

Dimensional Tolerances: Critical dimensions must be maintained within specified tolerances, typically ±0.0002″ for diameter and ±0.001″ for length, to ensure consistent tablet weight and thickness. Dimensional verification requires calibrated measuring equipment and documented procedures.

Carbide Material Standards

For carbide tablet punches, additional material requirements apply:

Carbide Grade Certification: Tungsten carbide grades must be appropriate for pharmaceutical applications, with documented grain size, cobalt content, and mechanical properties. Material certificates should include porosity levels, transverse rupture strength, and hardness values.

Cobalt Binder Content: The cobalt binder content should be optimized for pharmaceutical applications, typically 6-12%, balancing hardness with toughness. Higher cobalt content provides improved toughness but may reduce wear resistance.

Porosity Control: Porosity levels must be minimized to prevent bacterial harboring and facilitate effective cleaning. A-type porosity (isolated pores) should be virtually eliminated, while B-type porosity should be minimized according to established standards.

Manufacturing Quality Controls

Machining Standards

Tablet punch manufacturing requires adherence to strict machining standards:

Precision Machining Requirements: All critical surfaces must be machined to specified tolerances using appropriate cutting tools and techniques. Machining parameters should be validated to ensure consistent surface finish and dimensional accuracy.

Tool Wear Monitoring: Cutting tool condition must be monitored and documented to prevent degraded surface finish or dimensional drift. Tool change criteria should be established based on part quality rather than arbitrary tool life limits.

Workholding and Fixturing: Proper workholding techniques ensure consistent part geometry and prevent distortion during machining. Fixture design should accommodate thermal expansion and provide adequate support without inducing stress.

In-Process Inspection: Critical dimensions and surface finish should be verified during manufacturing using statistical process control techniques. Control charts and capability studies demonstrate process stability and capability.

Heat Treatment Validation

Heat treatment processes require comprehensive validation and control:

Temperature Uniformity: Furnace temperature uniformity must be verified through comprehensive surveys using calibrated instrumentation. Temperature variation should not exceed ±5°F throughout the working zone.

Atmosphere Control: Protective atmospheres prevent oxidation and decarburization during heat treatment. Atmosphere composition should be monitored and controlled within specified limits to ensure consistent results.

Cooling Rate Control: Controlled cooling rates ensure proper microstructure development and dimensional stability. Cooling curves should be documented and verified for each heat treatment cycle.

Hardness Verification: Post-heat treatment hardness testing verifies proper processing and provides traceability. Multiple hardness readings should be taken and documented for each batch of punches.

Dimensional Quality Control

Critical Measurement Requirements

Pharmaceutical tablet punches require precise dimensional control across multiple parameters:

Punch Face Geometry: The punch face profile directly impacts tablet quality and must be measured using appropriate techniques such as coordinate measuring machines (CMM) or optical profilers. Profile tolerances typically range from ±0.0002″ to ±0.0005″ depending on tablet requirements.

Concentricity and Runout: Concentricity between the punch face and barrel ensures proper seating in the tablet press and consistent tablet formation. Total indicator runout should not exceed 0.0005″ for critical applications.

Surface Roughness Measurement: Surface finish verification requires calibrated profilometers or similar instrumentation. Multiple measurements should be taken across the punch face to ensure uniformity and compliance with specifications.

Length and Diameter Control: Precise punch length and diameter control ensures consistent tablet weight and press timing. These dimensions should be measured using appropriate gauge blocks or calibrated equipment with documented uncertainty calculations.

Statistical Process Control

Implementing statistical process control (SPC) techniques ensures consistent quality:

Control Chart Implementation: X-bar and R charts should be maintained for critical dimensions to monitor process stability and capability. Control limits should be established based on process capability rather than specification limits.

Capability Studies: Process capability indices (Cp, Cpk) should be calculated and maintained above acceptable thresholds, typically 1.33 or higher for critical dimensions. Capability studies should be updated periodically to verify continued process control.

Measurement System Analysis: Gauge R&R studies should be performed on critical measurement systems to ensure adequate discrimination and repeatability. Measurement uncertainty should be less than 10% of the tolerance for critical dimensions.

Surface Quality Standards

Finish Requirements

Surface quality directly impacts tablet quality and cleaning effectiveness:

Roughness Specifications: Punch face roughness typically ranges from 8-16 Ra (microinches) depending on tablet formulation and quality requirements. Smoother finishes may be required for problematic formulations prone to sticking or picking.

Surface Defect Limits: Surface defects such as scratches, pits, or tool marks must be controlled within specified limits. Visual inspection standards should be established with photographic references and training materials.

Cleaning Validation Support: Surface finish specifications should support cleaning validation requirements by providing surfaces that can be effectively cleaned and verified. Rougher surfaces may harbor residues and complicate cleaning validation.

Coating and Treatment Standards

Surface treatments and coatings require specific quality controls:

Chrome Plating Requirements: Chrome plating thickness, hardness, and adhesion must meet specified requirements. Plating thickness should be verified using appropriate techniques such as magnetic or eddy current gauges.

Advanced Coating Validation: Coatings such as TiN, DLC, or other advanced treatments require comprehensive characterization including thickness, hardness, adhesion, and surface roughness measurements.

Coating Integrity Testing: Non-destructive testing methods should be employed to verify coating integrity and identify potential defects such as pinholes, delamination, or thickness variations.

Documentation and Traceability

Required Documentation

Comprehensive documentation ensures traceability and regulatory compliance:

Material Certifications: Complete material certifications must accompany each batch of tablet punches, including chemical composition, mechanical properties, and heat treatment records. These documents provide essential traceability for regulatory audits.

Manufacturing Records: Detailed manufacturing records should document all processes, inspections, and test results. These records demonstrate adherence to established procedures and provide evidence of quality control.

Inspection Reports: Comprehensive inspection reports should document all dimensional, surface finish, and visual inspections. These reports provide objective evidence of compliance with specifications.

Calibration Records: All measuring equipment used in tablet punch inspection must be calibrated and documented according to established procedures. Calibration records demonstrate measurement traceability and accuracy.

Traceability Systems

Effective traceability systems support regulatory compliance:

Unique Identification: Each tablet punch should carry unique identification that links to manufacturing and inspection records. Identification methods should be permanent and legible throughout the punch lifecycle.

Batch Control: Tablet punches should be controlled in batches with documented genealogy from raw materials through final inspection. Batch records facilitate investigation and recall activities if necessary.

Change Control: Any changes to punch specifications, manufacturing processes, or suppliers must be documented and evaluated through formal change control procedures. Impact assessments should consider effects on tablet quality and regulatory compliance.

Cleaning and Maintenance Standards

Cleaning Validation Requirements

Tablet punch cleaning procedures must be validated to ensure effectiveness:

Cleaning Procedure Development: Cleaning procedures should be developed based on the types of contamination expected and the cleaning agents compatible with punch materials. Procedures should specify cleaning agents, contact times, temperatures, and mechanical action requirements.

Analytical Method Validation: Analytical methods used to verify cleaning effectiveness must be validated for sensitivity, specificity, and recovery. Detection limits should be appropriate for the residue levels being monitored.

Worst-Case Scenario Testing: Cleaning validation should address worst-case scenarios including the most difficult-to-clean products, longest production campaigns, and most challenging contamination patterns.

Visual Cleanliness Standards: Visual cleanliness standards should be established with photographic references and training materials. Visual inspection should complement analytical testing to ensure comprehensive evaluation.

Preventive Maintenance Programs

Structured preventive maintenance ensures continued performance:

Inspection Schedules: Regular inspection schedules should be established based on usage patterns and historical performance data. Inspection frequency may vary based on product characteristics and production volume.

Maintenance Procedures: Detailed maintenance procedures should specify required activities, frequency, and acceptance criteria. Procedures should address cleaning, inspection, storage, and minor repairs.

Performance Monitoring: Key performance indicators should be monitored to identify degrading performance before quality issues occur. Metrics might include ejection forces, tablet defect rates, and dimensional changes.

Supplier Qualification and Management

Supplier Assessment Requirements

Tablet punch suppliers must be thoroughly evaluated and qualified:

Quality System Assessment: Supplier quality systems should be assessed for compliance with applicable standards such as ISO 9001 or pharmaceutical-specific requirements. Assessment should include document review and on-site audits.

Technical Capability Evaluation: Supplier technical capabilities should be evaluated including manufacturing equipment, measurement systems, and technical personnel qualifications. Capability assessments should verify ability to meet specified requirements.

Regulatory Compliance Verification: Suppliers should demonstrate compliance with applicable regulations and guidelines. This includes material sourcing, manufacturing controls, and documentation practices.

Ongoing Supplier Management

Continuous supplier management ensures maintained performance:

Performance Monitoring: Supplier performance should be monitored using metrics such as quality, delivery, and responsiveness. Performance trends should be tracked and addressed proactively.

Regular Audits: Periodic supplier audits should verify continued compliance and identify improvement opportunities. Audit frequency should be based on risk assessment and performance history.

Change Notification: Suppliers should be required to notify customers of any changes that might impact product quality or compliance. Change notification procedures should ensure adequate evaluation and approval before implementation.

Risk Management Framework

Quality Risk Assessment

Risk management principles should guide tablet punch quality decisions:

Risk Identification: Potential risks associated with tablet punch quality should be systematically identified including material defects, manufacturing variations, and handling damage. Risk identification should consider the entire punch lifecycle.

Risk Assessment: Identified risks should be assessed for probability and severity using established methodologies such as FMEA or risk matrices. Assessment should consider patient safety, product quality, and regulatory compliance impacts.

Risk Control: Appropriate control measures should be implemented based on risk assessment results. Control measures might include enhanced inspection, redundant testing, or alternative suppliers.

Risk Review: Risk assessments should be reviewed periodically and updated based on new information or changing circumstances. Review frequency should be appropriate for the level of risk involved.

Continuous Improvement Strategies

Performance Metrics and Monitoring

Continuous improvement requires comprehensive performance monitoring:

Quality Metrics: Key quality metrics should be established and monitored including defect rates, customer complaints, and inspection results. Metrics should be trended and analyzed for improvement opportunities.

Cost Metrics: Cost-related metrics such as punch life, replacement frequency, and total cost of ownership should be monitored to identify optimization opportunities.

Efficiency Metrics: Operational efficiency metrics including changeover times, cleaning effectiveness, and maintenance requirements should be tracked and improved systematically.

Technology Adoption

Emerging technologies offer opportunities for quality improvement:

Advanced Measurement Systems: New measurement technologies such as optical profilers and automated inspection systems can improve inspection accuracy and efficiency.

Data Analytics: Advanced data analytics can identify patterns and trends that support predictive maintenance and quality optimization.

Digital Documentation: Electronic documentation systems can improve traceability, reduce errors, and facilitate regulatory compliance.

Conclusion

Quality control standards for tablet punches represent a complex intersection of regulatory requirements, technical specifications, and practical manufacturing considerations. Success requires a comprehensive approach that addresses material standards, manufacturing controls, inspection procedures, and ongoing management throughout the punch lifecycle.

The regulatory landscape continues to evolve, with increasing emphasis on risk-based approaches, data integrity, and continuous improvement. Manufacturers must stay current with regulatory developments while maintaining robust quality systems that ensure consistent compliance and product quality.

By implementing the standards and practices outlined in this guide, pharmaceutical manufacturers can ensure their tablet punch quality control programs meet current regulatory expectations while supporting efficient, cost-effective operations. The investment in comprehensive quality control pays dividends through reduced regulatory risk, improved product quality, and enhanced operational efficiency.

For expert assistance with tablet punch quality control implementation and regulatory compliance strategies, contact our technical team for specialized consultation services.