Morse - O - Tool

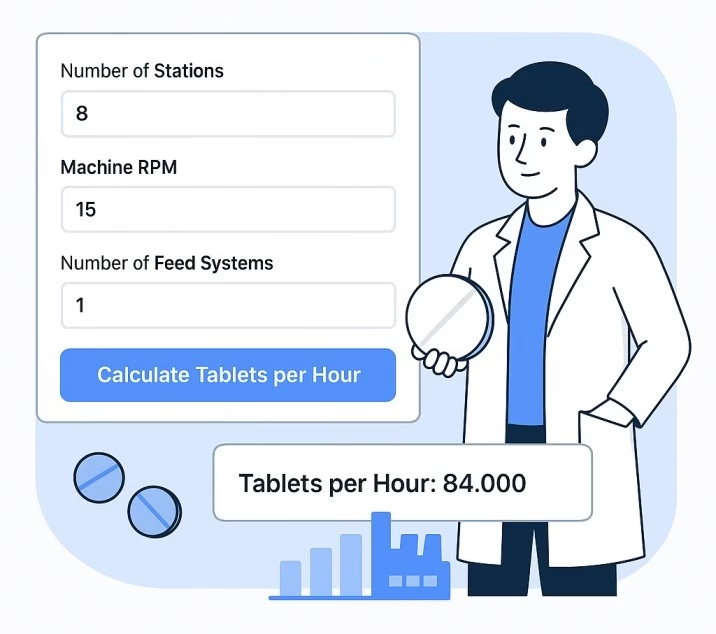

Tablet Compressed Per Hour Calculator

Time Required to Compress Tablets

Estimates output with machine precision

Supports batch planning & QA validation

Works seamlessly on mobile & desktop

Great for R&D and pilot-scale calculations

Saves time by eliminating manual formulas

No login required, instant results

Revolutionize Your Pharmaceutical Manufacturing: The Ultimate Tablet Compressed Per Hour Calculator Tool

Transform your tablet production planning with precision calculations that save time, reduce costs, and optimize manufacturing efficiency. Our free tablet compression calculator eliminates manual calculations and provides instant results for production planning across R&D, pilot-scale, and full production operations.

Why Pharmaceutical Production Planning Matters More Than Ever

The pharmaceutical industry operates under unprecedented pressure. With global demand for medications continuously rising and regulatory requirements becoming increasingly stringent, manufacturers face a critical challenge: how to maximize production efficiency while maintaining the highest quality standards.

The baseline pharmaceutical tablet processes require 170 h and consume 5600 kWh for one tables’ manufacturing batch. Process optimization can lead to significant improvements – studies show time reduction of approximately 71% was attained, and the reduction in GHG emissions and energy cost were 73.2%.

Modern tablet compression represents one of the most energy-intensive processes in pharmaceutical manufacturing, with the tablet segment leads the solid dosage form market by controlling more than 50% of global pharmaceutical production. Getting production calculations right from the start isn’t just about efficiency – it’s about competitive survival.

Introducing the Game-Changing Tablet Compressed Per Hour Calculator

The Morse-O-Tool Tablet Compression Calculator represents a breakthrough in pharmaceutical production planning technology. This precision-engineered tool transforms complex production calculations into instant, accurate results.

⚙️ Machine Precision Estimates

Generate output calculations with the same precision as your production equipment. The calculator accounts for real-world variables that affect tablet press performance, providing estimates that align with actual manufacturing conditions.

📈 Batch Planning & QA Validation Support

Streamline your production planning process with built-in validation features. The tool supports both small-batch R&D calculations and large-scale production planning, ensuring consistency across your entire manufacturing pipeline.

📱 Mobile & Desktop Optimization

Access your calculations anywhere, anytime. Whether you’re on the production floor reviewing equipment performance or in a boardroom presenting capacity analysis, the responsive design ensures seamless functionality across all devices.

🧪 R&D to Production Scale Support

Bridge the gap between laboratory development and full-scale manufacturing. The calculator handles everything from prototype batches to industrial-scale production runs, supporting the entire product lifecycle.

⏰ Eliminate Manual Formula Dependencies

Stop wasting valuable engineering time on repetitive calculations. What previously took hours of spreadsheet work now takes seconds, freeing your team to focus on process optimization and innovation.

🔒 Instant Results, No Login Required

Get immediate answers without bureaucratic barriers. No account setup, no data tracking, no corporate approval processes – just instant, accurate calculations when you need them.

The Science Behind Tablet Compression Efficiency

Understanding Production Capacity Fundamentals

Modern tablet compression operates on precise mathematical relationships. For all tablet press designs, the at any given press speed, the output is calculated by

Equation 1: Output (tablets/hour) = Press speed (revolutions/min) x Number of punch stations x 60 min/h

However, real-world production involves numerous variables that affect this baseline calculation:

Turret Configuration Impact: If the same tablet is produced at the same press speed with a 47 station TSM BBS turret, the output becomes 225,600 tablets per hour: an increase of 34%.

Multi-Tip Technology: Advanced tooling can dramatically increase output. Using a 5-tip tool configuration on the 59-station turret would achieve an output as follows: Output = 60 rev/min x 59 x 5 x 60 min/h = 1,062,000 tablets/h.

Process Capability and Quality Control

Production speed optimization must balance throughput with quality. Process capability values of 1.33 or 1.50, or higher, are generally indicative of a process that is under control, and process capability indices of greater than 2.0 would suggest that an increased press speed is possible while maintaining process quality.

Yield Optimization Factors

Most modern pharmaceutical manufacturers using state-of-the-art tablet presses will look to achieve final yields as high as 99% for single-layer tablets. Multi-layer yields are more challenging, given the number of different variables involved, with realistic figures often dipping closer to 85%.

Real-World Applications Across Pharmaceutical Manufacturing

Research & Development

Formulation optimization: Calculate material requirements for experimental batches

Scale-up planning: Predict production capacity needs before equipment investment

Process validation: Generate data for regulatory submissions

Pilot-Scale Operations

Batch scheduling: Optimize equipment utilization across multiple products

Resource planning: Accurate material ordering and waste reduction

Capacity analysis: Determine bottlenecks before full-scale production

Full Production Manufacturing

Production scheduling: Maximize throughput while maintaining quality standards

Equipment planning: Justify capital expenditure with precise capacity calculations

Operational efficiency: Identify optimization opportunities across product portfolios

Contract Manufacturing (CMO/CDMO)

Client proposals: Provide accurate timeline and capacity estimates

Resource allocation: Optimize facility utilization across multiple clients

Competitive bidding: Precise cost calculations for tender responses

Real-World Applications Across Pharmaceutical Manufacturing

Industry-Specific Benefits by Sector

Large Pharmaceutical Companies

Multi-site coordination: Standardize calculations across global manufacturing networks

Regulatory compliance: Generate consistent documentation for FDA and EMA submissions

Cost optimization: Identify the most efficient production configurations

Generic Drug Manufacturers

High-volume efficiency: Maximize output for cost-competitive products

Equipment ROI: Optimize existing press utilization before new investments

Market responsiveness: Quick capacity assessments for new product launches

Specialty Pharmaceutical Companies

Small-batch precision: Accurate calculations for orphan drugs and specialized formulations

Development efficiency: Streamline R&D to production transitions

Regulatory strategy: Support documentation with precise manufacturing data

Nutraceutical Manufacturers

Dietary supplement production: Calculate capacity for seasonal demand variations

Private label operations: Quick turnaround estimates for client proposals

Quality consistency: Maintain standards across diverse product lines